Brief Introduction of Internal Floating Roof Storage Tank

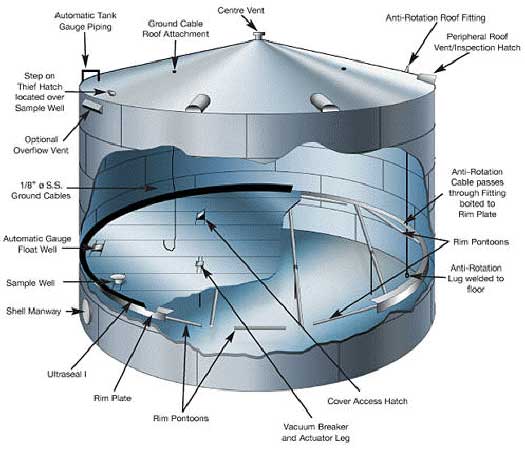

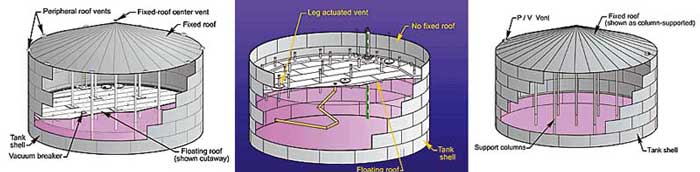

The outline structure of internal floating roof storage tank is roughly the same as that of dome oil tank. Compared with external floating roof tank, internal floating roof storage tank has a fixed roof, which is beneficial to improve the storage condition of oil products, especially to prevent the rain water from entering the oil tank and slow down the aging of sealing ring. At the same time, internal floating roof can effectively reduce the oil loss, therefore, internal floating roof storage tank has the advantages of fixed roof tank and floating roof tank. The American Petroleum Institute: the perfect designed internal floating roof is the best and lest investment method to control the oil evaporation loss of fixed roof tank so far.

Greatly Reduce the Evaporation Loss

As there is covered a floating roof, the stored liquid is separated with air, which reduces the air pollution and dangerous of explosion, so that it is easy to guarantee the quality of liquid. It is easy to transform the fixed roof tank into the inner floating roof tank, and cancel the respiratory valve, flame arrester and other accessories, less investment, obvious economic benefits. Because there is a fixed roof, it can effectively prevent wind sand, snow or dust pollution in the reservoir, to ensure the quality of the reservoir In a variety of climate conditions, it is called "all-weather storage tanks". At the same time, the load on the internal floating plate can be reduced, and the central drainage pipe, rotating floating ladder and other accessories can also be saved. The structure is simple, portable, easy to construct and maintain. Material of the sealing part can avoid the sun exposure and aging.

Under the same sealing conditions, compared with external floating roof tank, internal floating roof storage tank can further reduce the evaporation loss.

Comparison of Advantages

Fixed Roof Tank VS Internal Floating Roof Storage Tank- Material Loss and Environment Pollution

Big breathing loss: This is caused by the send and receive operations of tank. When feeding oil, the gas pressure in the tank is increased because of the increase of the liquid volume in the tank. When the pressure is increased to mechanical pressure limit, the breather valve opens automatically to exhaust. When oil is output from the oil tank, the volume of liquid in the tank is reduced, and the gas pressure in the tank is reduced. When the pressure drops to the limit of the negative pressure of the breathing valve, take in air. The loss caused by oil vapor and air induction of oil tank, which is because of oil transfer, is called “big breathing loss”.

Small breathing loss: Static stored oil products, the temperature is creased during the day because of the sunshine radiation, which will cause the gas expansion in the upper space and more evaporation of oil surface, then pressure in the tank will rise. When the pressure reaches the allowable value of the breathing valve, the oil vapor escapes outside the tank to cause loss. At night the temperature drops to shrink the gas in the tank, oil and gas condenses, then the tank pressure declines. When the pressure drops to the allowable vacuum value of breath valve, air enters into the tank in order to reduce the oil and gas concentration of gas space, and creates conditions for oil and gas evaporation after temperature rise. So repeated cycle, formed a small breathing loss of internal floating roof tank.

Internal Floating Roof Tank Of VS External Floating Roof Tank - Material Pollution and Complex Structure

Because the external floating roof storage tank has no fixed roof, dust, rain water is easy to accumulate, and even pollutes the oil. Instead, the internal floating roof tank with fixed roof is a good solution to this problem, what’s more, internal floating roof tank is additionally equipped with a rainwater drainage system, the sealing accessories is not easy to aging.